FC35 grade cast iron is capable of withstanding much greater stress without deforming and provides maximum vibration damping, which result in a machine that will outlast and outperform the competition. Built to endure years and years of rigorous high production turning, the heavily ribbed, one-piece thermally balanced bed and casting components are of FC35-Meehanite casting ( industry standard is FC25~30 ).The low centre of gravity 30° slant bed design provides the most rigid foundation possible for the headstock, turret, and tailstock. Major structural components have been combined into one solid platform.With bed lengths up to 3000mm and live tooling, C-axis, most lathes also available with Y axis, Goodway have a machine to suit any requirement. Covering turning diameter up to Ø970mm and spindle bores available up to Ø320mm, these powerful, maximum performance machines will easily accomplish the demanding turning applications required for large spindle bore lathes.

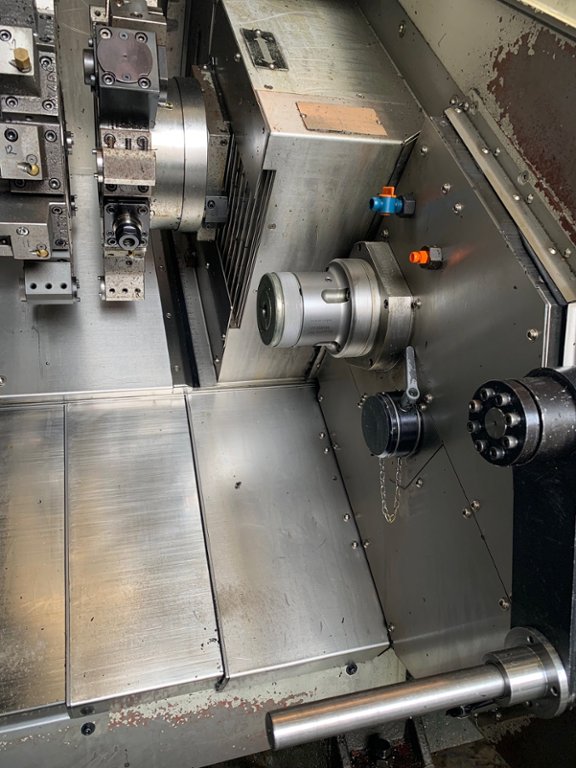

#GOODWAY LATHE SERIES#

The heavy-duty headstock is of one-piece casting reinforced with heat dispersing fins.Packed with industry leading technology and top quality components, the Goodway GS series slant bed turning centres combine incredible power, strength and speed to bring you The Ultimate Machining Power®.

Bearing configuration is designed for super heavy-duty cutting with ultra-smooth performance and long term durability with a higher level of accuracy.

#GOODWAY LATHE SOFTWARE#

Positioning of the tailstock has been simplified through use of custom software interface.

Packed with industry leading technology and top quality components, the Goodway GS series slant bed turning centres combine incredible power, strength and speed to bring you The Ultimate Machining Power®.

0 kommentar(er)

0 kommentar(er)